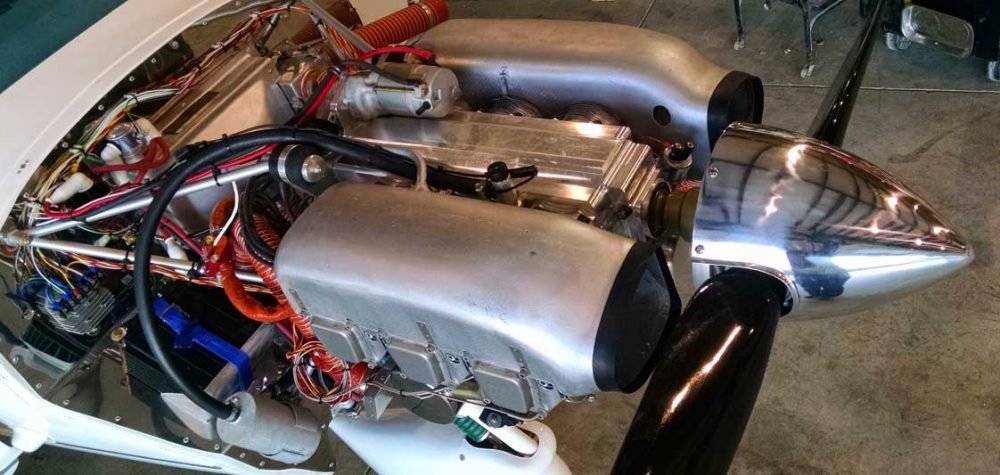

Limitations on the use of Jabiru engines have been lifted by Australia’s Civil Aviation Safety Authority (CASA) following a 20-month investigation into a series of engine failures.

The problems were through bolt and valve train failures in the Jabiru fleet in Australia, where the aircraft is frequently used for flight training.

CASA says that stock Jabiru engines maintained in strict accordance with Jabiru service bulletins and maintenance instructions are no longer affected by the limitations, which were issued in late 2014.

CASA’s 11-page report says the through bolts of early hydraulic lifter engines were susceptible to harmonic fatigue in certain situations. Later solid-lifter engines and the current production design roller-cam hydraulic lifter engines have not experienced any through bolt failures.

Service Bulletins

In 2012, Jabiru released its first service bulletin in an effort to improve the durability of the through-bolts. Several iterations of that service bulletin and an increase in the diameter of production through bolts and studs have resulted in an engine design with no further through bolt issues and a complete upgrade path for operators with the original 3/8in bolts.

The reported valve train issues appear to be caused by sub-standard maintenance practices and are not related to design or manufacture of the engine. Jabiru released comprehensive maintenance practices for the valve train around the same time the original CASA limitations were issued in late 2014. The roller cam followers and internal pushrod oiling of the latest generation Jabiru engine improve the operation of the valve train. Additionally, the latest piston design features valve-relief pockets to reduce the chance of catastrophic failure if a valve should ever stick open.

“The failures experienced can generally be attributed to the maintenance practices, not necessarily poor quality of maintenance but any deviation from the current Jabiru recommendations does appear to introduce conditions that can rapidly deteriorate the engine health to the point of failure,” says the CASA report.

“Hence, the current maintenance schedule (in particular 25hr oil changes) and the maintenance requirements for cylinder head inspections/maintenance per Service Letter JSL014 can be expected to provide for an acceptable level of reliable operation if they are adhered to with some vigilance.”

Good reliability

CASA engineers acknowledged that engines maintained in accordance with Jabiru instructions and that ‘use-approved’ parts have a good reliability record and should not be subject to the terms of the CASA restrictions.

The restrictions included flight in VFR day conditions only, no flight over densely populated areas, and an Acknowledgement of Risk document for passengers. They remain in force for operators of engines that are not in compliance with Jabiru maintenance instructions and service bulletins. They also remain for engines that are equipped with aftermarket parts not approved or manufactured by Jabiru because experimental parts introduce risks and variables that were not able to be studied.

In Australia, Jabiru has increased the frequency of its maintenance courses and has seen an increased amount of attention to its recommended maintenance practices since the CASA restrictions have been in place.

In a letter to owners, Jabiru founder Rodney Stiff wrote, “It is heartening to see recognition by CASA of the issues faced which are beyond our control and the steps taken by Jabiru to deal with the issues within our control. It has also been heartening to see the dramatic increase in compliance to Service Bulletins/Letters and maintenance procedures. This combined with our Jabiru engine training workshops has resulted in fewer incidents and puts us well ahead of (our competitors) for reliability.”

Read the full CASA report Jabiru Engine Reliability Analysis