Barn doors as flaps?

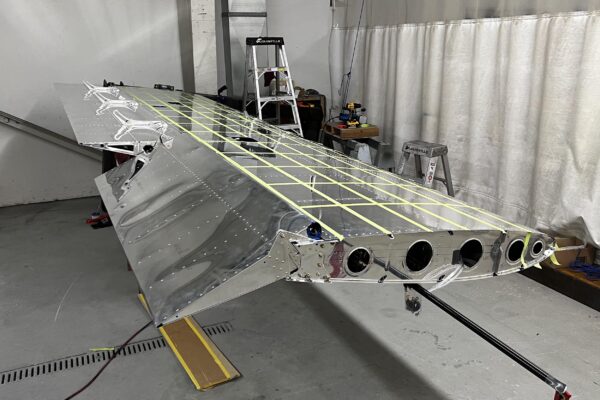

The Fowler flaps on the testbed RV-15 are huge and extend to 50° using an overhead handle mounted in the cabin ceiling. Rian admits they are an experiment because ‘we wanted to test some extremes’.

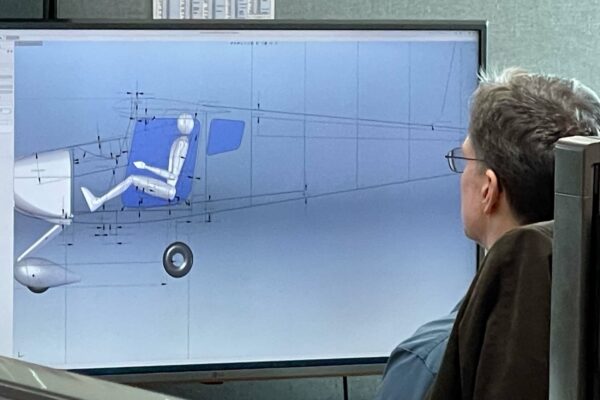

The large flaps work with an all-flying stabilator at the rear, chosen to avoid running out of elevator authority when landing on a really short strip such as a sandbar in a river. “Slow speed handling is key here,” said Rian.

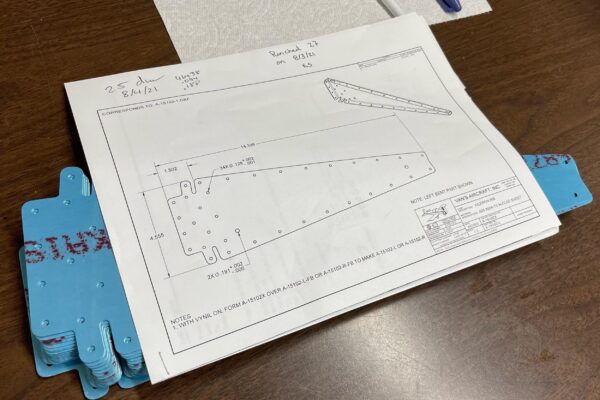

Unique wing

The RV-15 has a wing that’s a new design for Van’s and not borrowed from its previous designs (something that Van’s has done in the past). It’s big at 34ft wingspan with wingtips that add another foot. Rian wants to trim that back to 34ft overall so the aircraft fits easily in a standard hangar.

The wing shape (‘airfoil’) is designed to avoid aggressive wing drop at slow speeds, say when making a spot landing. Rian credits the success of the wing design to Van’s Engineering Director, Rob Heap. “Rob’s contribution to the wing, and getting all the elements right, like the ailerons and flap tracks is impressive. The fact the aircraft stalls straight ahead out of the box and flies as well as it does, shows what good work he did.”

High-lift with docile stall characteristics, with the aim to operate at low, rather than high deck angles (typically seen with wings that use high-lift devices), is the Holy Grail for backcountry aircraft.

Construction is conventional. It’s all-aluminium with wing spars carrying through the cabin ceiling and faired struts each side.