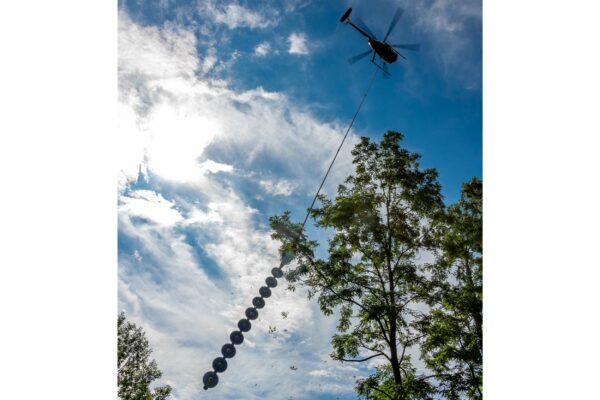

My job is fascinating, it’s 100% hands-on flying, demanding your complete attention at all times. With tree trimming there’s the saw, and when constructing powerlines, I fly aerial linemen as human external cargo. Holding someone 100ft below the helicopter, lowering them in between the powerline phases with only inches of clearance to do their work, requires you to be alert, precise and situationally aware. It’s definitely a team effort. We work in what’s known as the height-velocity diagram or dead man’s curve – this means in case of an engine failure, you can’t safely auto-rotate to the ground. So, excellent aircraft maintenance is of utmost importance.

What training did you have?

I have an FAA CPL(H), Transport Canada CPL(H) and EASA CPL(H). Rotor Blade provides extensive in-house training. All new pilots, whether they only have 1,500 flying hours or already 15,000 hours of vertical reference time, first become groundsmen.

They learn everything about saw maintenance before stepping into the helicopter. After riding along on short saw cycles, they practise picking up and setting down the saw, and eventually trim easier lines. On average it takes a year until you’re ready to fly the saw.

What’s been your favourite flight?

Working in Puerto Rico after Hurricane Maria destroyed the power grid in 2017. Together with thousands of linemen and multiple helicopters we rebuilt the power system. It was extremely satisfying to return power to the 3.4 million people who’d been living in darkness for up to 11 months. The island was beautiful despite the damage and the people were incredibly friendly.

And your favourite airfield?

Ted Stevens Anchorage International Airport. It’s the gateway to the last frontier, where beautiful snow-capped mountains meet the Cook Inlet. I’ve spent multiple summers in the backcountry, moving goldmine drills and flying cadastral surveys. As well as incredible scenery, Alaska has the world’s best salmon and halibut fishing, panning for gold along the river and enjoying time away.

Do you fly much outside of work?

Flying is my passion. I’m currently pursuing my fixed-wing and glider pilot rating. I’d love to fly a fixed-wing to Florida Keys for the weekend, or to the Appalachians to go camping with my fiancé and our dogs. Unfortunately, time outside work is limited.

What is your most valuable career advice?

In the helicopter industry, networking is of utmost importance. Most employment opportunities arise from a recommendation, so make sure to stay in contact with your peers.