A Van’s RV-9 kitplane believed to be the first powered by a Continental CD-155 turbodiesel engine has flown from South Africa to the UK.

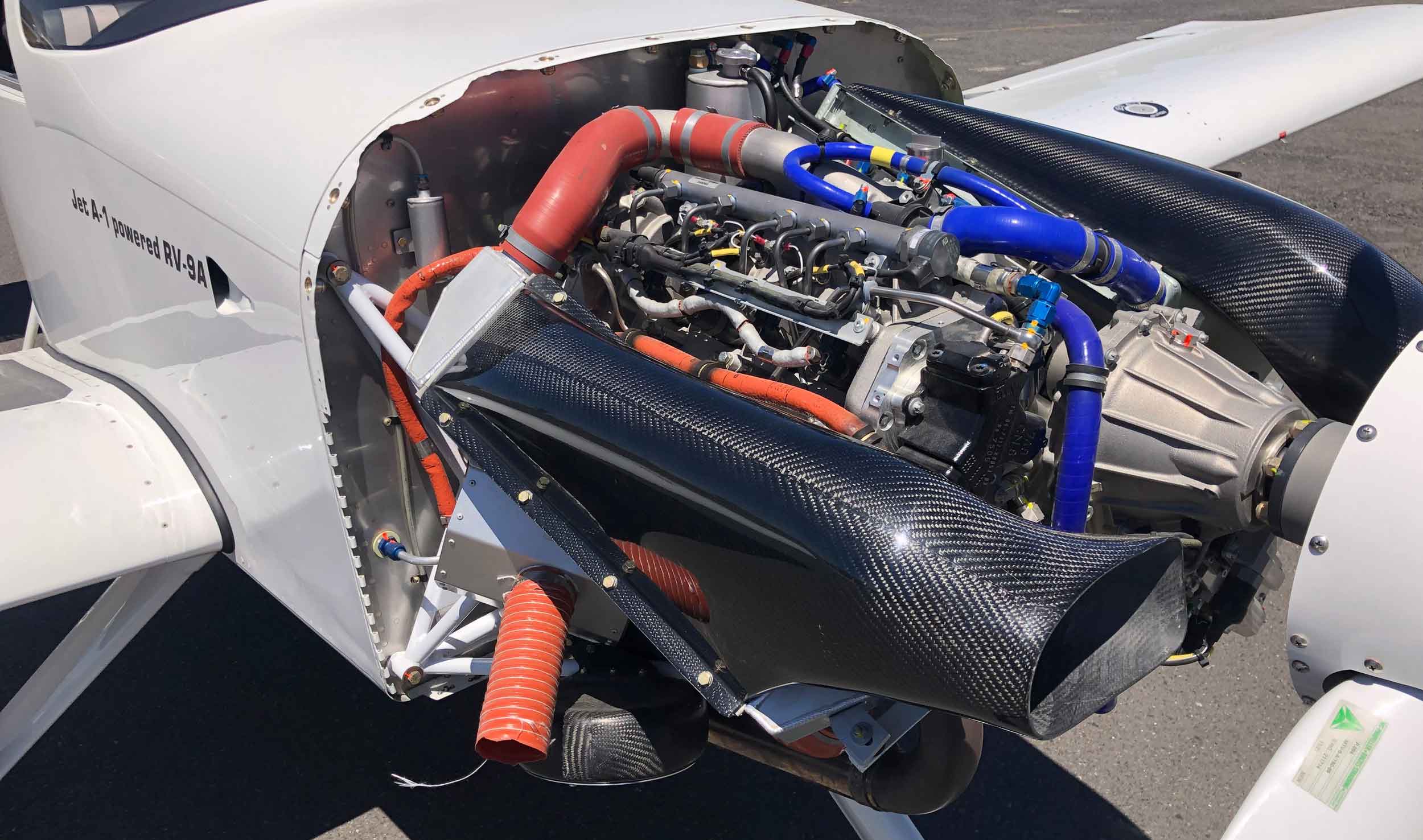

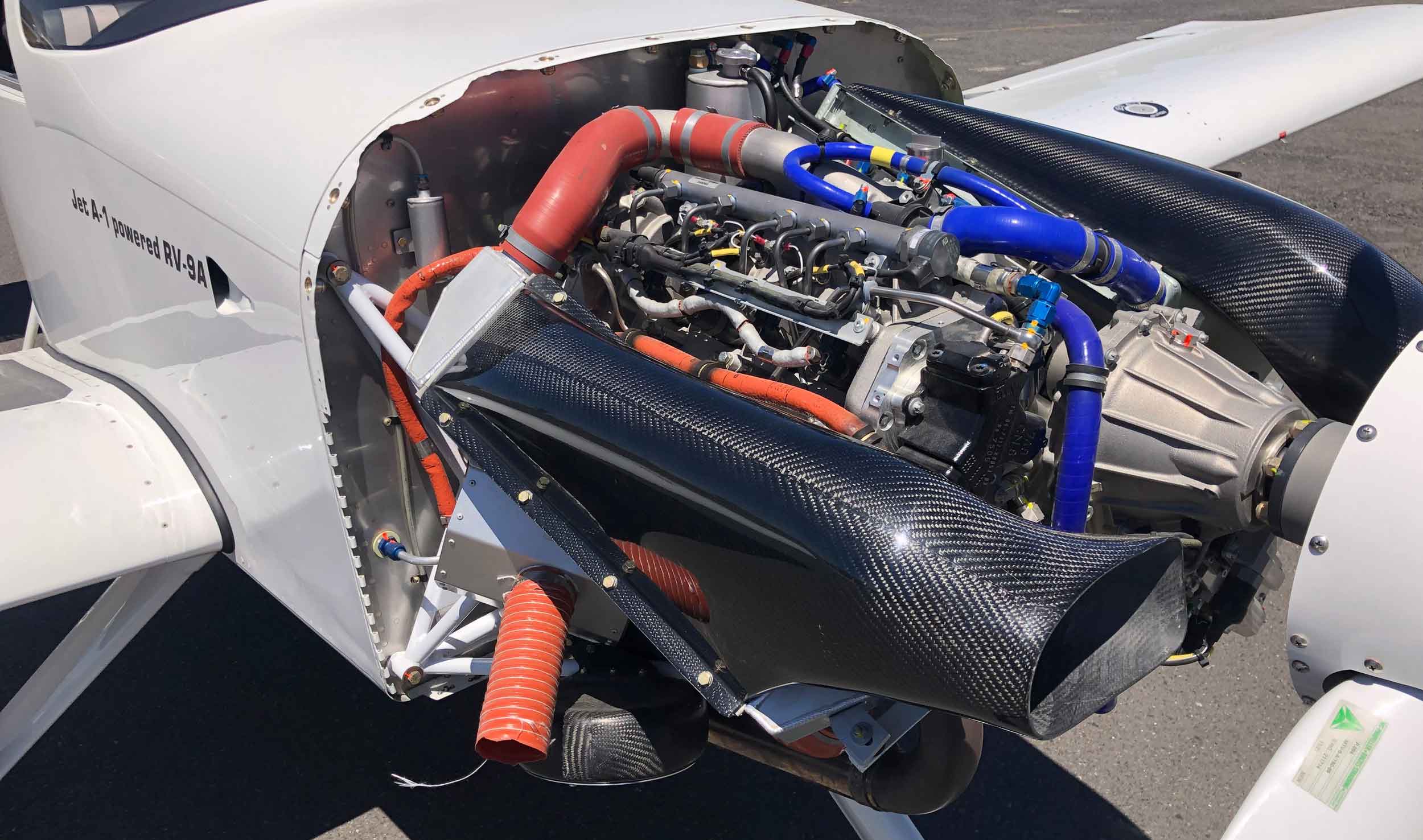

Gordon Bramire and Dennis Parker worked with South African specialists to build the aircraft and install the Continental engine in place of the standard Lycoming avgas engine.

The pair are talking to the UK’s Light Aircraft Association and others about making an engine conversion kit available for a range of Van’s kitplanes, and will be exhibiting the aircraft at April’s AERO Friedrichshafen on the Continental stand.

Dennis said, “While the Continental diesel used to be expensive compared to the Lycoming, the new acquisition price gap is narrowing. In places where there’s a greater price differential between Avgas and Jet-A1, it is starting to look very attractive.

“In the UK for example, running the diesel is around four times cheaper when you combine efficiency and fuel cost. We estimate your engine operating costs will halve wherever you are, even in the US. And you get to taxi to the Jet-A1 pump. That alone makes it worthwhile.”

Dennis and Gordon’s RV-9 will head for AERO Friedrichshafen in April

Dennis continued, “Our RV9 with the Continental Jet-A1 CD155 took to the skies in Capetown in January 2023. Gordon Blamire, my business partner, has extensive experience flying the Continental diesel with flight school PA28s and we’ve both flown Lycoming RV7 and RV9 variants. It was Gordon’s idea back in 2017 to pair the Continental engine with the RV9.

“Throughout the process we’ve looked to the experts. We studied the Glasair work done to install the CD135 diesel, and Kurt Goodfellow helped us with initial considerations for the engine mount.

“We consulted with Ken Krueger (ex Vans) on design viability. Robin Coss Aviation in Capetown did the RV build and engine installation work. They have built more RVs than anyone in the world and produce RV aircraft of stunning quality.

Continental’s CD-155 turbodiesel powerplant fits neatly into the RV-9 and the team is working on a conversion kit for other RVs

“Most importantly, we worked with Continental in Germany to provide oversight, design, and quality checking. We wanted to ensure the engine installation met their high installation standards from the outset.”

The downside of using the Continental engine is weight – it’s 38.5kg (85 lb) heavier than a Lycoming O-320. To keep the centre of gravity within limits, the battery and some avionics were moved from the firewall/panel to behind the aft bulkhead.

“The aircraft is meeting every expectation,” said Dennis. “We climb at 1400 feet per minute and true out at 163 knots at 10,000 feet using 7.8 gallons per hour. Pull the engine back to 75% power and we are seeing 154 knots at 6 gallons per hour.”

Their next project is to pair a Van’s RV-14 with a Continental CD-170.

Continental Diesel