Flying the 'Shark'

Anequim HAS Been flown by only one pilot, Gúnar Armin Halboth. Gúnar is a professional pilot, rated in many types. After the Brazilian airline Varig imploded, he flew in the UK as a Boeing 737 captain for Ryanair. He returned to Brazil to fly bizjets and is currently flying helicopters for a corporate client. Current in light aircraft as well, he competes at Brazil’s highest aerobatic levels in his Pitts, and set records in an earlier Iscold aircraft, the CEA 308.

As the new records testify, Anequim is very, very fast… but what is it like to fly? We asked Gúnar for his description.

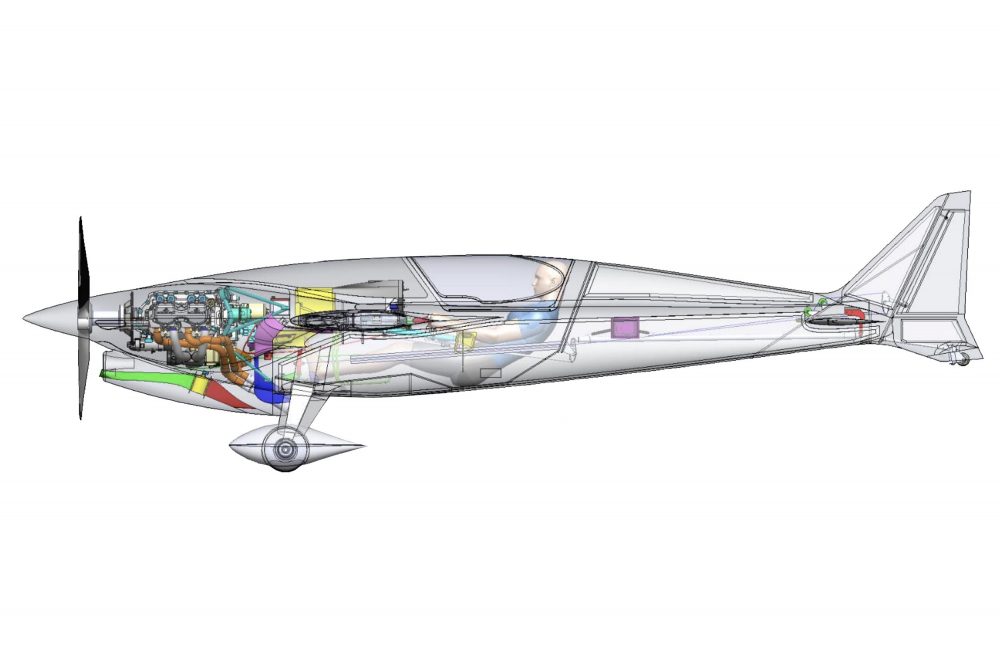

“Anequim is a tiny airplane. When I get in I have to cross my arms to reach the canopy latches on either side. It is my first side-stick airplane, which I found works very well even with a very short stick. Trim is electric (more on that later) mounted on top of the stick. Flaps are also electric; a small turn knob on the right side actuates with my left hand.

“As to the view from the cockpit… well, there really isn’t much. You can’t see straight forward on either take-off or landing. That’s why I have never operated on runways narrower than 30 metres. Directional control on take-off is not difficult. The rudder is very light and I operate it with my toes. Initial acceleration is not fast because of the very-high-pitched, fixed-pitch propeller. After several hundred metres the tail is up and as the airplane leaves the ground things start to happen more quickly. With the three-blade climb prop we used for the 3,000-metre time-to-climb, it’s a whole different shark! On that attempt, the take-off roll was brutal. In less than seven seconds I rotated, with the tailwheel still on the ground, to a 30° pitch-up. I could see the horizon below my wings! Rate of climb was incredible. I remember checking it while crossing 6,000ft and it was about 4,000fpm.

“Control forces are well-balanced. It feels something like an RV-6 but it is slightly heavier on roll and more neutral, due to the lack of dihedral. On early flights we had more aileron movement and a heavier feel. But as the ailerons are really effective, I asked Paulo to change the leverage. Now I have less aileron deflection, though still more than enough, and a lighter feel.

“Elevator feel is a tricky thing on fast planes. It was an issue on CEA-308. At low speeds something like an RV feels very good, but imagine yourself flying one at more than 260kt. It would be almost impossible to avoid high g loads. We’ve created a very simple electric spring trim system that, while trimming forward for high speeds, increases the tension, keeping the force-to-g response almost constant from 75 to 300+ knots.

“The rudder is very light, perhaps more than ideal, but nothing that requires a change. Overall, very nice handling indeed.

“Landings are challenging, mostly because Anequim just doesn’t like to slow down. Forward visibility is very bad, worse than a Pitts or Christen Eagle from the forward seat. The wing in landing position stays almost exactly at the horizon line, so you lose a good reference. We have split flaps on the trailing-edge of the wings. They are there to add drag and help give some sort of reasonable descent angle. On the first flight they failed to stay down and it took four attempts to land, finally switching the engine off in the flare and using all of the 1,500m runway to get down. Typically, I like to cross threshold above 85kt (in most cases 95+) and landing happens at about 72kt.

Of course, approach angle is still shallower than average.

“So far I have never tried a wheel landing. We have limited prop clearance (none at all with the larger-diameter, climb prop) and I feel the stiff gear would probably try to kick me back in the air. No brakes required at all for directional control but you do need them to stop. Because of the very reclined position, more than a glider, I have to really tighten my seat-belt to keep my body from slipping back while using the brakes on landing. A normal seat-back gives you more support than you realise!

“If there’s anything better than the speed of Anequim, it’s the reliability. Since the beginning, only once have we gone to the airfield and not flown – and that was due to a dead battery.

Anequim is still under development, but the flying qualities and reliability are quite sufficient. We are also sure we can improve all the records we’ve already achieved.”