Once I’d climbed in, it was just a matter of making my way towards the front and the right-hand seat. Everything about this aeroplane says ‘bloody tough’, there’s probably more weight in the many, many rivets than there is in all the skins; the undercarriage looks as if would support something twice the size and the various levers… but I’ll get to them later.

Originally, Grumman fitted the Widgeon with a pair of inverted six-cylinder Ranger engines with 200hp per side, but somewhere along the way Chester’s Widgeon, N86638, was converted and had a pair of Continental O-470-M fitted, which added another 30hp per side while removing the complexity of the other aftermarket options, which included both radial and geared engines from Lycoming. With both engines running at idle, we set out along Lindy Loop (a taxiway) for the pumps. The side windows on each side slide backwards, so while Chester concentrated on avoiding trees, golf carts, pedestrians and other aircraft, I sat there waving hello to residents pottering away in their hangar homes.

Fishing and flying

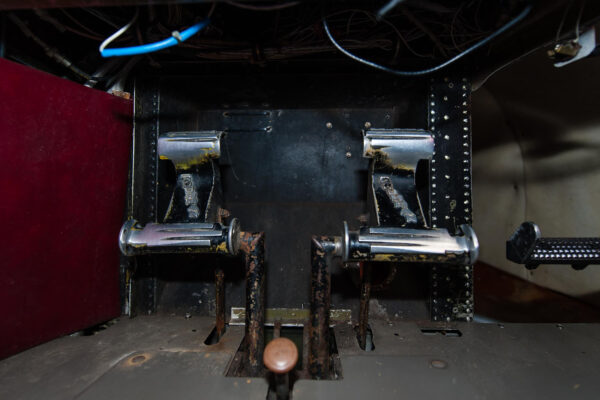

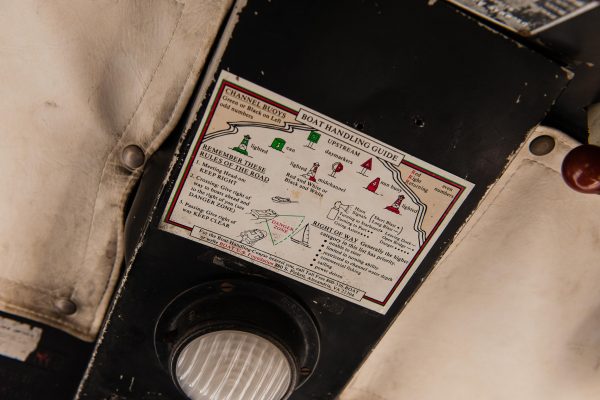

Tanks filled and everyone briefed, I jump in and try to focus while I absorb the details in the cockpit. The instrument panel is fairly familiar, but there’s a ceiling panel full of extra bits and pieces ahead of you, another control panel above and behind your head, gear position indicators behind each of the crew seats, a door ahead of the right seat rudder pedals that can be kicked open to reveal a passage to a hatch that opens on top of the nose to help with docking (not to be used in flight, so no Kate Winslet, “I’m flying, Jack” moments) and much of it seemingly festooned with heavyweight handles, levers and knobs. Ahead and in the middle of the ceiling are the throttles and prop controls, while on the upper rear control panel (that’s the one behind your head) you’ll find similarly styled levers for selecting and cross-feeding fuel tanks and for adjusting the mixture. There are curiosities like an automatic bilge pump switch, an anchor light and, right above the throttles, three mag switches – a set for each engine and a push/pull switch in the middle that cuts them all off with one quick pull (like the Kate Winslet hatch it’s best not to use this one in flight).

Unlike the fuel-injected engine in the Cessna 172 I’d been wrestling with, the carb’ed Continentals started easily and we taxied to the runway (after making sure the tailwheel was unlocked – that’s one of the levers in the ceiling). Steering is by rudder, a bit of differential power and differential braking (toe-brakes on the left-hand side only) – talking of brakes, there’s another knob sticking out from the floor on the left that looks a bit like a single heel brake, although it’s rarely used; this is the parking brake… I mean, why wouldn’t you put it there? This aeroplane was built four years before the word ergonomics had been officially accepted.