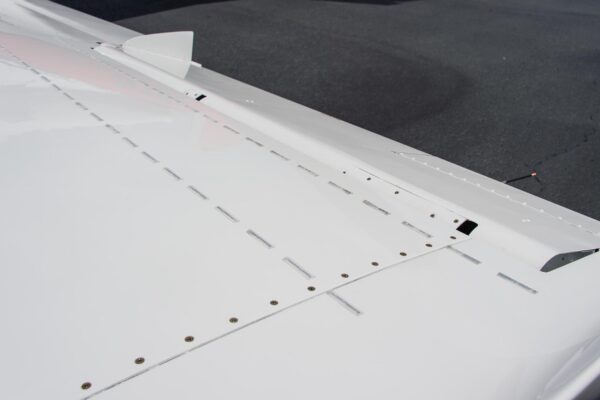

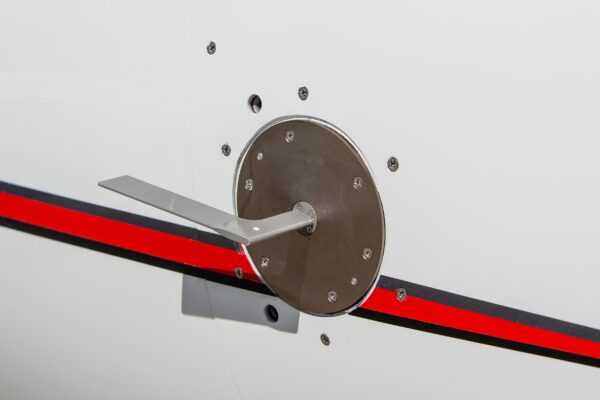

Matt Bergwall, Cirrus Aircraft’s Vision Jet Product Line Manager, offered us the chance to test the Vision Jet over a couple of days’ flying, with an overnight stop. Matt had already done a thorough pre-flight, so before we climbed in, all that was required was to load the bags for four of us into the unpressurised rear baggage compartment, take a look at the oil level – there’s a sprung flap you push open to check a sight gauge on the starboard side of the engine nacelle – remove the chocks and have a good look to make sure there’s nothing lying around on the wing, fuselage or nearby floor which might get sucked into the engine.

Big windows

While FLYER’s Ed Hicks and Thomas Borchert of the German mag Flieger are settling in the rear cabin, I take a little time to think about the Vision Jet’s journey from mock-up to certified reality, and about how its development sometimes took place ‘at the speed of cash.’ I’ve waited a long time to sit in the front, left-hand seat of the SF50, in fact there were occasions when I thought it’d never get finished, but it’s real, I’m there and we’re about to go flying.

Right, back to the job in hand. I know I’ve mentioned the big windows before, but they make a huge first impression, so much so that the dual, 14-inch avionics screens, which would dominate any other cockpit, look well-proportioned in here.

“The dual, 14-inch Garmin Perspective Touch screens would dominate any other cockpit but look well-proportioned in here”

The avionics system, known as Perspective Touch by Garmin, is basically the company’s G3000, tailored to and integrated with the SF50. Underneath the PFD and MFD, are three GTC580 touchscreen controllers, to their right there are the environmental controls and underneath them the autopilot control head. The throttle – sorry, thrust lever – sits on a pedestal, alongside a manual trim wheel and the fuel tank selector. Above your head is the big-boy jet stuff – emergency, quick-don oxygen masks, a guarded cabin pressure dump switch and a guarded engine fire toggle switch with two push-to-discharge buttons. Oh, I nearly forgot, unlike any other Cirrus, the SF50 has a landing gear lever right in the middle of the two main avionics screens.

Both batteries go on and the avionics start to come to life and initialise. I split the left-hand PFD, bring up the before-start checklist and start to work my way through it, acknowledging every item with the push of a button.

You can imagine my hands moving fluidly between the controls – master of all that I survey. I can imagine it too, but I’m buggered if I can do it for real, so instead I clumsily and laboriously make my way through the list, one painful item at a time, until I get to the interesting bit: starting the engine. By my left hand there’s a rotary dial with just two positions, Off and Run. I turn it to the Run position and listen to check that the fuel pump’s going – it is – so all I need to do now is to briefly push the engine Start/Stop button and the FADEC does the rest. There’s a gentle whine, a whoosh and engine instruments with such expensive-sounding labels as N1, N2 and ITT come to life.

As a pilot you have no real input into the start sequence other than pushing the button. If there’s a problem or it exceeds limits, the FADEC should shut everything down – if it doesn’t then you have to – but that’s about it.