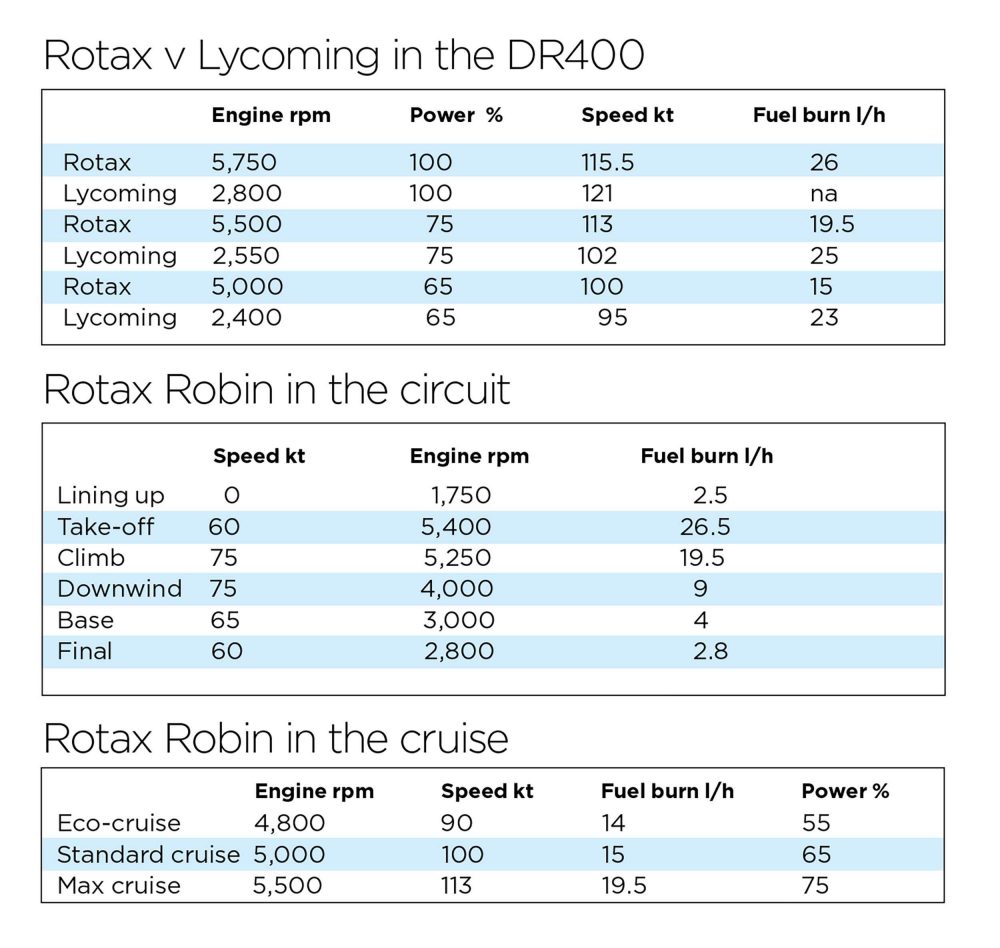

The basic concept is simple: a fuel-injected Rotax 912 iS Sport installed at the front end of a DR400 airframe. The objectives are clear: a reduction in fuel cost; less noise; easy access for maintenance; higher safety; reduction in CO2 emissions; simple operation; plus better cross-country performance. In a nutshell, a reliable aeroplane at an affordable price – an aeroplane that is economical and reduces noise for neighbours.

A number of people were already working along these lines, but French aircraft engineer Gilles Aurensan has actually done it.

By nature, Gilles is reserved, but he is readily forthcoming when talking about this subject. Together with fixed-wing and helicopter private pilot Karine Baillou, they run aircraft maintenance company Nogaro Aviation.

For the last 10 years, Gilles noted how French aero-clubs had suffered under the increasing price of fuel and noise complaints from neighbours. Further, although VLAs (very light aircraft) looked promising, they were often found to be less robust when used in the club environment. So, when the fuel-injected Rotax was announced in March 2012, Gilles at once saw an opportunity to match the well-proven DR400 wooden airframe with a quiet engine combining economy with reliability.

Gilles said, “We had both the DR400 fuselage and a Rotax available. It seemed to us that the Rotax iS was a modern design, so we worked towards creating an interface between the two with the minimum of changes.”

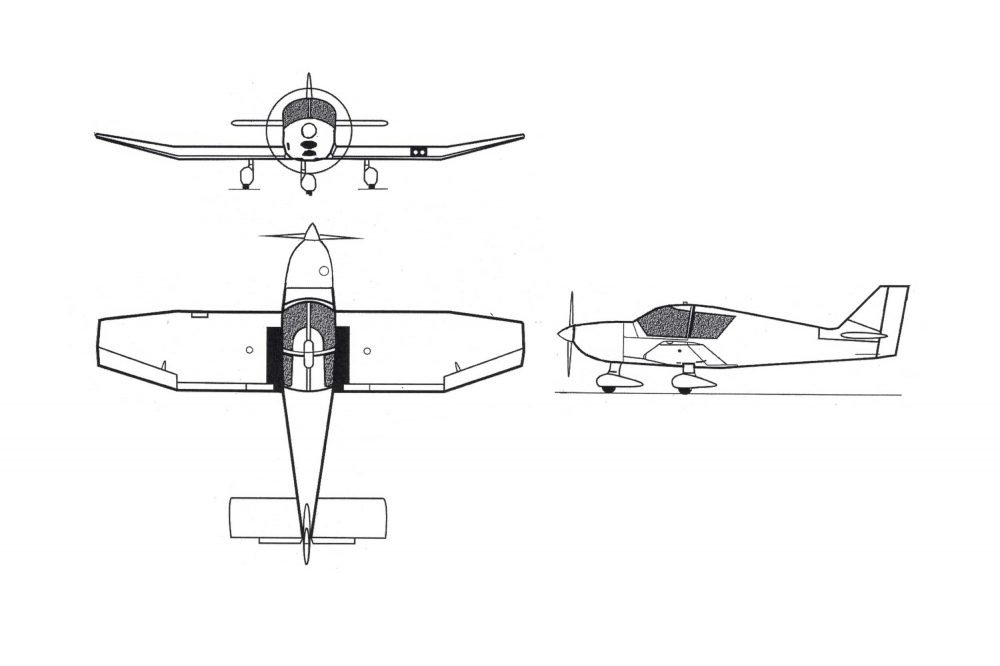

Since the Rotax with accessories is 60kg lighter than the Lycoming, they had to move the engine forward to keep the centre of gravity in the right place. Gilles decided to develop a Supplemental Type Certificate with EASA, permitting the modified DR400 to continue under its current certificate of airworthiness. He hired certification specialist Velica SAS to do the STC, and Bordeaux engineering consultants Innovamech to design an intermediate engine bearer.

He explained, “We decided to keep the original Robin engine mount and the same Rotax fittings, linked by an intermediate bearer moving the Rotax about 20cm forwards to keep the C of G in the right place.”

The intermediate unit has been made stronger than necessary to take an engine delivering up to 150hp and weighing 150kg – Gilles is already working on the installation of a turbocharged, injected, 135hp Rotax 915.

The final installation still leaves space for add-ons, and mechanics like the fact that, with the cowling off, access for maintenance is easy. Gilles has now reduced the empty weight by nearly 100kg (60kg on the aircraft structure, and 40kg less fuel for the same maximum endurance).

Nogaro is a small regional airport in the Armagnac region of France, and on the ramp stands DR400-120 Dauphin F-GORZ. It’s hard to believe the aircraft has already flown 10,500 hours, because it looks to be brand new. But then I should add that Nogaro specialises in rebuilding Robin aircraft.

Ever since its first flight powered by the Rotax iS on 14 December 2015, ’RZ has progressed with no problem to complete about 15 hours and 30 test flights. At present, the aircraft has completed the testing for the STC, and Nogaro is in the process of completing the EASA certification paperwork.