N450DM was delivered on December 31 1953 (didn’t they have parties to go to?), it spent some time in corporate service, was rebuilt and refurbished several times, despite sustaining damage that put it ‘beyond repair’, and eventually ended in the custodianship of the Marco family in Jacksonville, Florida. I think it would be fair to say that for David Marco there’s only one kind of aeroplane and that’s a perfect aeroplane. After owning the Beaver for the best part of 15 years, in 2013 it went to Wipaire for a full restoration that took the best part of nine months. The Marcos spent countless hours deciding on modifications that would result in a lightweight, working aeroplane without losing that vintage feel, and given the Beaver’s long history there are lots of mods available that will undoubtedly keep the type flying in commercial service for years to come.

Working modifications

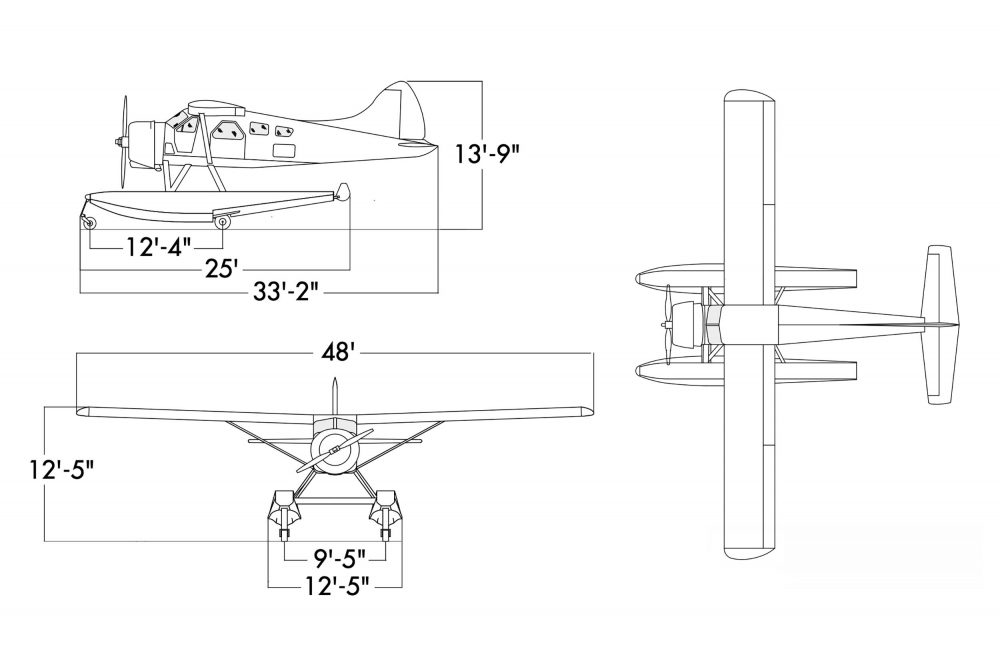

The first and most obvious modification comes in the shape of the Wipline 6100 amphibious floats. These give the flexibility to land on err, land, or to land on water with the wheels up, or to make a really short, one time only landing on water with the wheels down; considerable effort and attention is expended on avoiding the latter.

The Wiplines have more internal storage space and thanks to their 6,100lb rating they can easily cope with any increased gross weights. Every operator wants a higher gross weight (more weight usually equals more money) and the Beaver’s spoilt for choice with Wipline, Kenmore and design holders Viking Air all having kits available. The Marcos chose the Wipline kit which gave an increase of about 370lb. If you are operating the Beaver on anything other than amphibs it’s possible to go all the way to 5,600lb, a modification that most Alaskan working Beavers enjoy, and one that pretty much means you can carry almost anything you can load. The Wipline kit for the Marco Beaver means that the total fuel load (spread between five tanks, three in the belly and one in each wing) is137usg. That means an endurance of about five hours with 30 minutes reserve. To save you doing the maths, that means the Beaver will burn about 95lph, so planning for a nice round figure of 100lph should mean no awkward silences.

Next up in the modification stakes are a pair of aileron flow accelerators – think one big VG per wing. The Beaver has ailerons that droop with flap, and without the accelerators, aileron control apparently becomes a bit ponderous when you have a lot of flap combined with not very much airspeed. I’m told that’s something that can get your attention when approaching a short gravel strip.