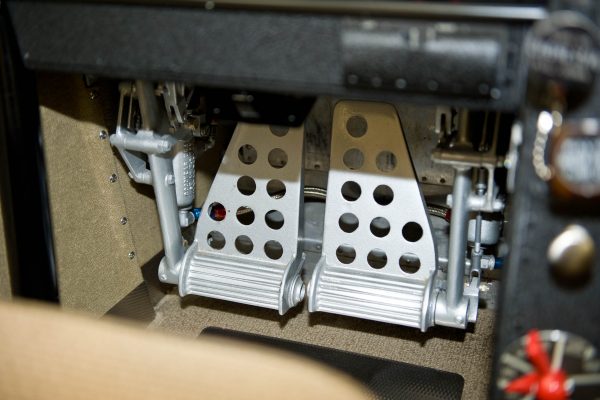

With outside duties complete, we climb in and buckle up. It’s a big aeroplane but extra space wasn’t wasted on the flight deck so while it’s not a tight fit, there’s not that much room to spare either.

The engines start very easily and, while we wait for things to warm up, I try to imagine what it would have been like for the pilots to operate these as corporate transport. Time to pay attention, time to taxi, time to look out for the tips of those long wings, time to wonder how much of a view out there will be through the letterbox-shaped front window.

Before taking the runway, we run through the checks for each of the big P&Ws. Although the engines are run up to 1,800rpm in turn, it feels wonderfully remote sat up here, our backsides a good six feet off the ground. Everything is fine and we brief the take-off. Dave tells me that he has no plans to fail anything, so if something does happen it’ll be for real.

There are two big, guarded, red organ-stops at the top of the panel; pushing them in will feather the related propeller. We know they both work and I know exactly where my hand is going should the need arise. Dave casually mentions, in passing, that it can all get a bit loud in the cockpit.

A quick check that Joe and Ed are ready in the photo aircraft, a call to the Tower controller and we’re cleared to line up and take-off. On the runway the fuel pumps go on, and when we’re lined up the tailwheel is locked. Power is brought up to 25 inches, everything is in the green and we’re good to go. Take-off power is about 35 inches and 2,300rpm, and somewhere between 25 and 35 inches and without warning, the gentle, luxurious, lumbering Lockheed turns into a fire-spitting, eardrum-busting beast.

The engine’s soothing and melodic bass notes at idle are shoved aside by a rush of avgas and replaced by a monumentally thunderous roar. The propellers are no longer cajoling the air, but thrashing each and every molecule into submission, and each bullied bit of air is screaming obscenities about the violent assault.

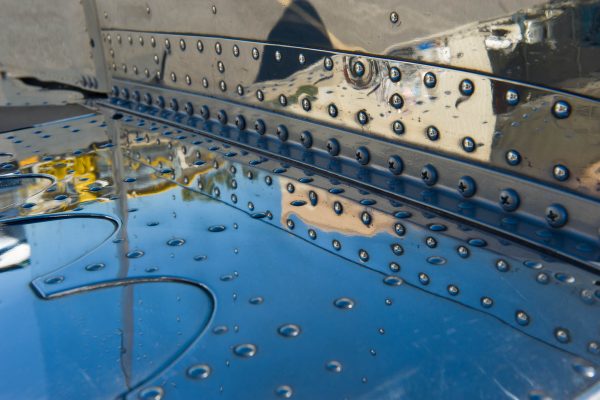

The prop tips, not quite supersonic, are still describing their wide arc at something like Mach .97, and if that’s not enough of a sensory onslaught the whole thing is accompanied by a high frequency vibration that’s making its way through my body via my backside – think sitting on a two-stroke chainsaw at full chat.

The Lockheed is now starting to hurry down the runway and out to my right I briefly catch sight of Joe and Ed waiting at the hold in the C182. I swear I can see them both, eyes wide open, ears bleeding and mouthing “Awesome!” in unison as they are overcome by the overwhelming combination of polished aluminium beauty and a wave of raucous decibels. The inane grin has gone, a huge smile now in its place, I might even be dribbling. 1938 aviation is truly magnificent.