I am watching from the tree-lined shore of the Oshkosh seaplane base, as a beautiful, twin-engined Grumman Goose follows a float-equipped Piper Cub out into the sheltered cove. The Goose is quite a big machine by most private pilot standards – I’m sure the Cub pilot would think that – but both are about to vanish from my view.

They’ve not taken off, but have both disappeared behind the red and white form of the lake’s biggest airborne visitor to date, the Hawaii Mars, one of two Martin Mars seaplanes owned and operated as fire bombers by Coulson Flying Tankers of Port Alberni, British Columbia.

It’s a few seconds before the smaller aircraft reappear, long enough to let you know that the Mars is one big aeroplane – a bit like going flying in the Albert Hall.

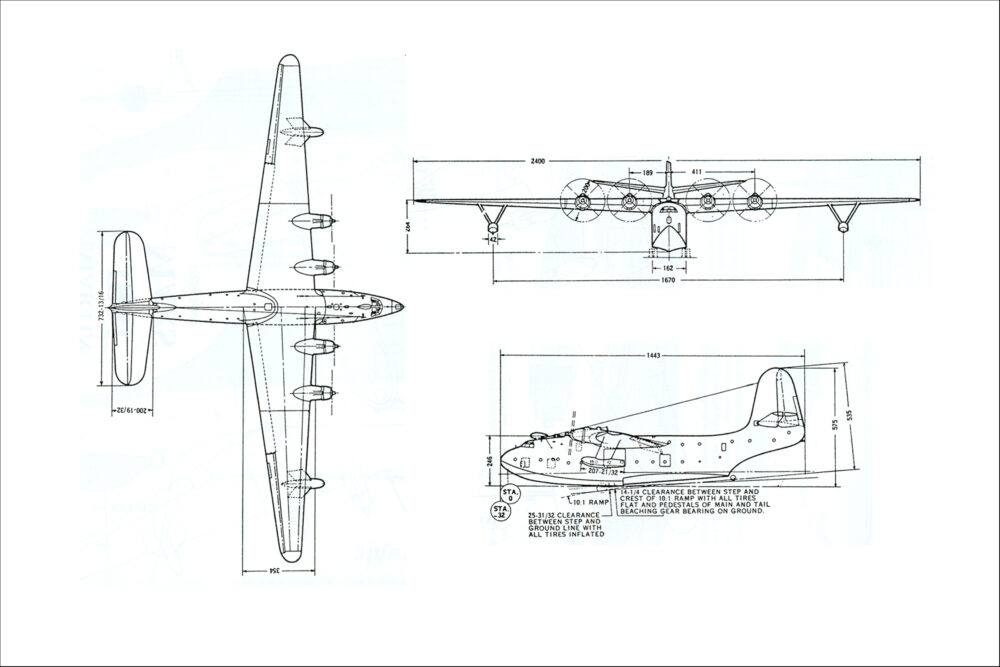

Firefighting certainly wasn’t what Glenn L Martin had in mind for the Martin Mars. Originally conceived as a patrol bomber for the US Navy, the first Mars flew in July 1942, sporting twin fins, mounted on the ends of the tailplane.

One year later, with testing complete, the bomber concept was considered obsolete, but a need for a large transport aircraft meant that an order was placed for 20 of the design, which now sported a giant single fin.

In the end, only six were completed, and while two were lost early on in accidents, the “Big Four”, as the remaining Navy Mars were known, were operated till 1956 amassing nearly 70,000 hours. During that time they collected a number of world records for airlift and endurance, all of which still stand today.